The aim of this project is to 3D print the Rygo with a DShape and install it outside of Gropp's Gallery in Vancouver. After some consolation with artist Bathsheba Grossman and Enrico Dini (inventor of the DShape), we decided to go with the Rygo. Now I am putting together a group of like-minded people to make a video to promote the project and decide what rewards would work best.

The video will have to be short (2 minutes or less), explaining what we are making, how we are making it and what people will get back in return.

What people will get back in return is a mix of access to the project, actual 3D prints (some printed by an ordinary printer, others by a DShape). The smallest will be things like thank you notes or internet control of the internal light of the sculpture (you can view via webcam). Low mid-range will be prints by our partner Buildatron. High mid-range rewards will be 3D prints of the Rygo. High-range rewards will be small prints by the DShape.

Contributions by donors will go towards the printing costs (about 3000 Euros per cubic meter), shipping costs (between 300-600 dollars per cubic meter or ton, which ever is highest), smoothing, finishing and installation (2,000 dollars).

We hope to get this project on Kickstarter or IndieGoGo by mid-January 2012 for 60 days.

Entrepreneur looking for investors to start up a company in large scale 3D Printing.

Wednesday, December 21, 2011

Friday, December 9, 2011

Too Many 3D Printing Companies

Although 3D Systems has made it their goal to buy every single 3D printer manufacturer (i.e. ZCorp, Bits from Bytes), dozens of new ones are popping up (Buildatron, Printr, UP!, Techzone, Open3DP). So, all the technical expertise (and patents) are being eaten up by one company while a billion others without the expertise (but the tenacity) are proliferating. One wonders - are we gonna get good printers from these new companies, or is 3D Systems (or other big companies...Stratsys) are gonna bust out a kick-ass low-cost printer and wipe the floor with these new startups.

Ponderous.

Well. Let's look regular 2D printers - 3D printer's older and better known cousin. They are difficult to run sometimes and break down, not to mention, run by a few big companies that tie their customers to their ink to keep printer costs low. I would place 2D printers as one of the more unreliable and bloated member in Consumer Electronics. Will 3D printers suffer the same fate?

As always, "The Oatmeal" is spot on.

Full Piece Right here

Ponderous.

Well. Let's look regular 2D printers - 3D printer's older and better known cousin. They are difficult to run sometimes and break down, not to mention, run by a few big companies that tie their customers to their ink to keep printer costs low. I would place 2D printers as one of the more unreliable and bloated member in Consumer Electronics. Will 3D printers suffer the same fate?

As always, "The Oatmeal" is spot on.

Full Piece Right here

Wednesday, December 7, 2011

Air Sponge

A few images of an invention I wish to develop in the future. Let's just say, we 3D print it and it cleans the air with a nano particle treated surface.

Sunday, December 4, 2011

The Fog That's Killing Us

Today it was announced that CO2 emission rose dramatically in 2010....bad news as it is, the worst part is that it was an unprecedented increase. Its on the high end of the IPCC's estimates for C02 emissions, trends that equate with a +2 C degree increase by 2100. For those unaware of that number, any increase of 2 degrees or more won't just hurt the earth (and by extension, us) but perhaps hurt its ability to sustain life in general. While we may concern ourselves with trivialities of celebrity life or fashion, we're killing the planet.

Concrete manufacturing (heating kilns to prepare cement), transportation (moving minerals and material), extraction (getting gypsum and aggregates) and impacts related to its use (manufacturing and discarding of formwork, use of rebar, poorly built structures that make building less energy efficient) we can be concerned. Concrete accounts for 7% of CO2 emissions, and we can reduce that significantly if we used 3D printing. But why?

Using local materials, we print everything. Using less formwork and labour, we reduce emission by complimentary goods. By using 3D modelling and programming, we can create more efficient buildings. One way is using the shape of the building to maximize energy use. Another is geometry - more flexibility and freedom in construction = less material used = less emissions. Whatever material we don't use in a DShape is reused. Whatever building we tear down we can reuse by crushing it up into aggregate and using it.

If you're worried about emissions, so am I. But there are solutions. It just means the concrete industry is going to have to realize they have to undergo deep structural change in how they operate, otherwise they'll be going out the door like the oil industry, the music or film industry.

Concrete manufacturing (heating kilns to prepare cement), transportation (moving minerals and material), extraction (getting gypsum and aggregates) and impacts related to its use (manufacturing and discarding of formwork, use of rebar, poorly built structures that make building less energy efficient) we can be concerned. Concrete accounts for 7% of CO2 emissions, and we can reduce that significantly if we used 3D printing. But why?

Using local materials, we print everything. Using less formwork and labour, we reduce emission by complimentary goods. By using 3D modelling and programming, we can create more efficient buildings. One way is using the shape of the building to maximize energy use. Another is geometry - more flexibility and freedom in construction = less material used = less emissions. Whatever material we don't use in a DShape is reused. Whatever building we tear down we can reuse by crushing it up into aggregate and using it.

If you're worried about emissions, so am I. But there are solutions. It just means the concrete industry is going to have to realize they have to undergo deep structural change in how they operate, otherwise they'll be going out the door like the oil industry, the music or film industry.

Saturday, December 3, 2011

Crowd-funding DShape

I've been considering Crowd-funding over the past few days - it makes complete sense to crowd-fund a sculpture. Here's why.

Great opportunity

-3D Printing is sexy and other printistas have managed to crowd-fund their designs. The most telling is Joshua Harkers Crania Anatomica Filigre He offered rewards like posters, thank you notes and a 3D print for certain donations amounts. And violá!, he raised 77,000 dollars from almost 1000 backers! So having a cool 3D print is worth it to people!

Marketing

-My aim is to market the DShape and find investors. Crowd-funding is much better aligned with my interests and abilities because I have really only involved myself in the music industry - we are all about grassroots funding! Getting a lot of people to donate a little bit rather than one person to give a massive amount is what I think would fly faster. So far all the investors i talk to mention the recession. Ditto, its an emergent technology....why would I invest when i have no clue what sales or interest are like?

This vision plays in the Grass.

Furthermore, I want DShape to be rooted in DIY rather than big-investor types....at least until we find the right, respectful investor. If this project is successful, that shows an aspect of solidarity with people's wishes to see something truly beautiful that they voted for with their cash instead of some bumpkiss pretentious architecture because it was backed by one developer's tasteless pile of money to make tasteless bullshit because they have no fucking taste.

Control

Although we're choosing the sculpture - its only because there are limitations on what we can make. I had this fear that the first investor would want a sculpture of himself and his fucking dog. If we're making a bold move, it has to seem honest. It is also an opportunity to properly sand and smooth the sculpture.

Space

Im moving back to Gropps Gallery after almost 18 months out.. we have a space to install the piece! Its near downtown, and its visible to the public. Also, we have the tools to properly install it.

So this is the plan for the next few months. Ive been in contact with a few designers...usually mathematical artists....George Hart, Carlos Sequin and (please!) Bathesheba Grossman. Depending on what prints best, we will choose one of these. I put a craigslist ad but all i got were character artists...should have been specific.

Mermaid's Delight by George Hart

http://virtualmathmuseum.org/mathart/ArtGalleryGeorge/mermaids_delight.html

Enchinoderm by George Hart

http://www.georgehart.com/sculpture/echinodermania1.html

Tower by Carlos Sequin

http://www.cs.berkeley.edu/~sequin/X/Tower_Model/TowerModel_FDM.JPG

Once we have a design, we price out the costs. I want the standard thank you note, poster and tshirt from 1 - 40. Plus, there will be a chunk of 3d printed material (i wish it was something designed...OH SHIT YES. I had a great idea. How about a 3D printed Pet Rock?) 50 to a 100 rewards are actual 3D prints from shape ways of our design. From 200 upwards we were thinking of actual DStone prints using the leftover space in the bounding box. Ring set..like, linked chains of rock. Also, lamps...because they're easy to make. This all depends on what design we choose, the level of support structure 'within' the bounding box. In all likelihood, we may get Enrico to do a small print run of separate objects and send them here to be repackaged and sent to their respective donors.

Once that is figured out, we develop a video and the project site. Also - must find an american with an account...kickstarter only 'operates' in the US.

And of course, I have to get back to VANCOUVER! Im in ottawa and not to happy about it. SHould have left earlier. But then again, i have all this free time to develop this project. By the time December 31st rolls around, i should be ready to sell.

There are, of course, challenges. A single cubic meter of printed sculpture cost 2000 Euros...after shipping....maybe 2500 or about 3400 dollars. So, we have to raise between 10,000 and 20,000 dollars. Is that even POSSIBLE?

Great opportunity

-3D Printing is sexy and other printistas have managed to crowd-fund their designs. The most telling is Joshua Harkers Crania Anatomica Filigre He offered rewards like posters, thank you notes and a 3D print for certain donations amounts. And violá!, he raised 77,000 dollars from almost 1000 backers! So having a cool 3D print is worth it to people!

Marketing

-My aim is to market the DShape and find investors. Crowd-funding is much better aligned with my interests and abilities because I have really only involved myself in the music industry - we are all about grassroots funding! Getting a lot of people to donate a little bit rather than one person to give a massive amount is what I think would fly faster. So far all the investors i talk to mention the recession. Ditto, its an emergent technology....why would I invest when i have no clue what sales or interest are like?

This vision plays in the Grass.

Furthermore, I want DShape to be rooted in DIY rather than big-investor types....at least until we find the right, respectful investor. If this project is successful, that shows an aspect of solidarity with people's wishes to see something truly beautiful that they voted for with their cash instead of some bumpkiss pretentious architecture because it was backed by one developer's tasteless pile of money to make tasteless bullshit because they have no fucking taste.

Control

Although we're choosing the sculpture - its only because there are limitations on what we can make. I had this fear that the first investor would want a sculpture of himself and his fucking dog. If we're making a bold move, it has to seem honest. It is also an opportunity to properly sand and smooth the sculpture.

Space

Im moving back to Gropps Gallery after almost 18 months out.. we have a space to install the piece! Its near downtown, and its visible to the public. Also, we have the tools to properly install it.

So this is the plan for the next few months. Ive been in contact with a few designers...usually mathematical artists....George Hart, Carlos Sequin and (please!) Bathesheba Grossman. Depending on what prints best, we will choose one of these. I put a craigslist ad but all i got were character artists...should have been specific.

Mermaid's Delight by George Hart

http://virtualmathmuseum.org/mathart/ArtGalleryGeorge/mermaids_delight.html

Enchinoderm by George Hart

http://www.georgehart.com/sculpture/echinodermania1.html

Tower by Carlos Sequin

http://www.cs.berkeley.edu/~sequin/X/Tower_Model/TowerModel_FDM.JPG

Once we have a design, we price out the costs. I want the standard thank you note, poster and tshirt from 1 - 40. Plus, there will be a chunk of 3d printed material (i wish it was something designed...OH SHIT YES. I had a great idea. How about a 3D printed Pet Rock?) 50 to a 100 rewards are actual 3D prints from shape ways of our design. From 200 upwards we were thinking of actual DStone prints using the leftover space in the bounding box. Ring set..like, linked chains of rock. Also, lamps...because they're easy to make. This all depends on what design we choose, the level of support structure 'within' the bounding box. In all likelihood, we may get Enrico to do a small print run of separate objects and send them here to be repackaged and sent to their respective donors.

Once that is figured out, we develop a video and the project site. Also - must find an american with an account...kickstarter only 'operates' in the US.

And of course, I have to get back to VANCOUVER! Im in ottawa and not to happy about it. SHould have left earlier. But then again, i have all this free time to develop this project. By the time December 31st rolls around, i should be ready to sell.

There are, of course, challenges. A single cubic meter of printed sculpture cost 2000 Euros...after shipping....maybe 2500 or about 3400 dollars. So, we have to raise between 10,000 and 20,000 dollars. Is that even POSSIBLE?

Friday, November 18, 2011

Business as Unusual

Back in Canada! Its good to be home. Let me give you the run down of Europe and my return.

I visited Enrico Dini in Pisa, Italy and developed a deal to bring the D-Shape to Canada. I saw his machine, I saw the prints and I saw the future. We both hit it off very well, talking about what we could make with this machine, his own successes and failures and my own aspirations. Right now I have the rights to sell his printing services and patent license in Canada. So the clock is ticking to find clients and investors.

That was October 5th. Now its November 18th and I have a lot of things on the go. I have my friend Marcelo in Bolivia coding my website, I have brochures to edit and business cards to buy. I have to find seed capital and clients. Enrico has been selling his services to landscape architects, printing beautiful pieces like this below:

This is a print by Rinus Roelofs - a Dutch Mathematician and designer...and developed the 3D modeling program Rhino! I dont see why anyone WOULDNT want one in their garden.

Since I got back to Ottawa on Monday I've met up with a few interesting people...Ian Graham of the Code Factory, a smattering of business types at the Chamber of Commerce and architects at a party. Their response was partly open-mouths and partly excited chatter - which means nothing if they don't sign a check and get things REALLY moving. What I am lacking are a few small stl models and a piece of printed rock to show. I emailed Enrico and they are (apparently) in the mail right now.

On the side, I've been dreaming up some ideas of other applications - mostly combining Ti02 and the DShape. These will be coming down the tube in the next few years if everything goes to plan.

Website will be up soon peeps! For now, I will give you an excerpt from one of our brochures.

I visited Enrico Dini in Pisa, Italy and developed a deal to bring the D-Shape to Canada. I saw his machine, I saw the prints and I saw the future. We both hit it off very well, talking about what we could make with this machine, his own successes and failures and my own aspirations. Right now I have the rights to sell his printing services and patent license in Canada. So the clock is ticking to find clients and investors.

That was October 5th. Now its November 18th and I have a lot of things on the go. I have my friend Marcelo in Bolivia coding my website, I have brochures to edit and business cards to buy. I have to find seed capital and clients. Enrico has been selling his services to landscape architects, printing beautiful pieces like this below:

This is a print by Rinus Roelofs - a Dutch Mathematician and designer...and developed the 3D modeling program Rhino! I dont see why anyone WOULDNT want one in their garden.

Since I got back to Ottawa on Monday I've met up with a few interesting people...Ian Graham of the Code Factory, a smattering of business types at the Chamber of Commerce and architects at a party. Their response was partly open-mouths and partly excited chatter - which means nothing if they don't sign a check and get things REALLY moving. What I am lacking are a few small stl models and a piece of printed rock to show. I emailed Enrico and they are (apparently) in the mail right now.

On the side, I've been dreaming up some ideas of other applications - mostly combining Ti02 and the DShape. These will be coming down the tube in the next few years if everything goes to plan.

Website will be up soon peeps! For now, I will give you an excerpt from one of our brochures.

The D-Shape™ can use a vast number of materials as an aggregate, ranging from 0.2 to 60 mm in granular size. Sand, gravel, cement, rubber, cork, sawdust, grinded rejects, ceramic shards, crushed glass, pumice, polystyrene, polyurethane, expanded clays, wax spheroids, cellulose grains, etc.

Virtually any fibre, microfibers or nanofibres can be added into the granular material. Polymeric fibres, glass fibres, basalt fibres, vegetable fibres, synthetic fibres, etc.

Any of the above can be mixed together with the D-Sand to produce your design.

A liquid is needed to dissolve and hold the D-Salt, our inorganic binder that is deposited by the DShape onto your mix of D-Sand and the aggregate. The dissolved D-Salt reacts with the D-Sand and binds the aggregate together. This liquid must have a viscosity between water and that of honey, such as water, water based solutions, alcoholic solutions, Pre-polymers, etc.

Assuming that the liquid is able to cement together the grains of the mixture, is easy to see that the materials that can be printed with D-Shape are endless. Colour and texture of a print can be completely different from one material to the next. However we must carefully examine your design and the demanded material to see if it is printable to our standard.

Monday, September 26, 2011

The News

Hi there. In America now. On my way to Europe momentarily. I decided to browse through the internet for recent news in 3D printing. One blog entry about the legal problems of printing weapons (specifically, a rifle magazine of 10 rounds. More than 10 can put you in prison!) And another article about how thieves used a 3D printer to steal 400,000 USD! Oh and 3D systems has released another printer that is not cheap ($14,500) but prints in 6 colours and is 5 times faster than similar printers. The right sort of price for schools, offices and maybe the odd consumer. If you think consumers would buy it, remember that the first Personal Computers like the Macintosh cost half that.

I spent time in NYC checking out the sights and of course, MakerFaire 2011. I saw a few cool things, but I came for the 3D printers. Makerbot was there....and I saw a few printers Ive always wanted to see. Fab@home wasn't as impressive as i thought. Been kind of skeptical of their syringe methods. But printing in Fudge is always a big hit with the audience. Techzone was there...but Ive built their Huxley and it was a BITCH. I met the good men of Buildatron and loved their work. Their new printer is derived from the same Huxley. I wanted to help them out and share a few of my own solutions but sadly there was no time. Ultimaker was kicking butt...by far the best competitor in my opinion. 3D systems was out in force in disguise with their latest acquisition, BotMill. I hate and fear 3D systems simply because of their size and aggressive take-over the industry. I have a good feeling its going to be something like a wack-a-mole. To be fair, a product that can reproduce most of its components is likely an unsellable item. As long as the technology is difficult to use and quality is hard to come by, they'll be fine. But the fact is that quality, speed and materials are following a pseudo-Moore's Law. Perhaps 10 years down the road 3D systems will simply transition to consulting because they can't compete with cheaper models, just like Xerox. (Xerox was forced by anti-trust agencies to give up its patents to photocopy technology in the 1970s. In 10 years they went from 100% marketshare to something like ... 20%?? Guess why? The Japanese made better ones)

The take-away? 3D Printing was representing! The public is becoming a little more aware and they have ideas of their own. That bodes very well for us. But this is still a hacker/DIY arena to play in because .... we dont have the ol' "3D Print" button ready....its a difficult enterprise to print things. So Apple introduced GUI to computer and made a quantum leap (Again, THANK YOU XEROX) in computer-consumer interface. Let's see what comes down the pipeline cost/interface -wise.

I spent time in NYC checking out the sights and of course, MakerFaire 2011. I saw a few cool things, but I came for the 3D printers. Makerbot was there....and I saw a few printers Ive always wanted to see. Fab@home wasn't as impressive as i thought. Been kind of skeptical of their syringe methods. But printing in Fudge is always a big hit with the audience. Techzone was there...but Ive built their Huxley and it was a BITCH. I met the good men of Buildatron and loved their work. Their new printer is derived from the same Huxley. I wanted to help them out and share a few of my own solutions but sadly there was no time. Ultimaker was kicking butt...by far the best competitor in my opinion. 3D systems was out in force in disguise with their latest acquisition, BotMill. I hate and fear 3D systems simply because of their size and aggressive take-over the industry. I have a good feeling its going to be something like a wack-a-mole. To be fair, a product that can reproduce most of its components is likely an unsellable item. As long as the technology is difficult to use and quality is hard to come by, they'll be fine. But the fact is that quality, speed and materials are following a pseudo-Moore's Law. Perhaps 10 years down the road 3D systems will simply transition to consulting because they can't compete with cheaper models, just like Xerox. (Xerox was forced by anti-trust agencies to give up its patents to photocopy technology in the 1970s. In 10 years they went from 100% marketshare to something like ... 20%?? Guess why? The Japanese made better ones)

The take-away? 3D Printing was representing! The public is becoming a little more aware and they have ideas of their own. That bodes very well for us. But this is still a hacker/DIY arena to play in because .... we dont have the ol' "3D Print" button ready....its a difficult enterprise to print things. So Apple introduced GUI to computer and made a quantum leap (Again, THANK YOU XEROX) in computer-consumer interface. Let's see what comes down the pipeline cost/interface -wise.

Tuesday, July 5, 2011

Gone Climbin'

I've been going to climbing gyms since I was a young guy ... and they were always fun. However, once you've actually climbed real rocks - the gym doesn't compare. Essentially, Climbing Gyms are modernist nightmares with boltholes for attaching what resembles a robust chunk of dry paint. These indoor gyms are fun - but only because the real cliffs aren't around. Too bad we can't have real rock.

Enter - large scale 3D printing...

Use simple 3D sculpting software, maybe use some randomized filters and 'aging' to create the appearance of 'real' rock, and we have a climbing wall! Well, technically a pillar....but it is what it is. By printing out a design like mine below, we can have something closer to the real experience of rock climbing. When you think about it, large format printing like the DShape is just accelerated sedimentation - yet we can control it.

I am clueless to what makes a 'perfect' wall for climbers, but I'm certain lots of them would love to work these sort of walls.

Enter - large scale 3D printing...

Use simple 3D sculpting software, maybe use some randomized filters and 'aging' to create the appearance of 'real' rock, and we have a climbing wall! Well, technically a pillar....but it is what it is. By printing out a design like mine below, we can have something closer to the real experience of rock climbing. When you think about it, large format printing like the DShape is just accelerated sedimentation - yet we can control it.

I am clueless to what makes a 'perfect' wall for climbers, but I'm certain lots of them would love to work these sort of walls.

Sunday, June 19, 2011

The Promise of White Paint

Its been known for a while now that Titanium dioxide is a photo-catalysts - it can attract smog compounds like NOx and other Volatile Organic Compounds from cars and industry and use sunlight to break them down.

There are restrictions - there must be a high surface area ... often by coating a mesoporous surface (think of Pumice stone) and other compounds (like soot) can accumulate and inhibit its abilities. On the other hand, bacteria and biofilms cannot adhere to this surface...one in part to how TiO2 attracts water as well under UV and breaks it into OH and H compounds that kill them off easily. When night falls, the un-energized TiO2 molecules release the H20, carrying off bacteria and other contaminants. And if that's not enough for you, we can use TiO2's properties to cool houses down very easily. If water is slowly applied to the surface, we can cool the building and everything inside through evaporation - just like the Human Body does with sweating. (There's a wonderful paper from Hong Kong called "Photocatalytic construction and building materials: From fundamentals to applications" ... I can't link the .pdf, but it might be out there on the internet somewhere.)

So, I see a few things coming out of this. First, highways and roads can have median barriers replaced with something resembling a 'sponge', printed with a Dshape. TiO2 would either be part of the material, or applied later. I suspect that we could get higher surface areas that with precast, and thus passively clean air better.

Another one uses TiO2s properties to cool housing efficiently and thus saving money on AC. I'm really amazed by this possibility....mostly because it provides another reason for using 3D printing. Small holes for water would be part of the structure ... placed strategically to cool the whole building. The massive savings on energy costs would be a big part of selling large-scale 3D printing as a better bet in construction.

Anyways....i've been trying to figure out how to 3D model an ordinary Concrete median with Voronoi diagrams to get my idea across.....Meshlab keeps on crashing..woot! Autocad 2011 for Mac is still giving me trouble.....Having a mac is not the best for 3D design sometimes...

Lo vemos.

JF

There are restrictions - there must be a high surface area ... often by coating a mesoporous surface (think of Pumice stone) and other compounds (like soot) can accumulate and inhibit its abilities. On the other hand, bacteria and biofilms cannot adhere to this surface...one in part to how TiO2 attracts water as well under UV and breaks it into OH and H compounds that kill them off easily. When night falls, the un-energized TiO2 molecules release the H20, carrying off bacteria and other contaminants. And if that's not enough for you, we can use TiO2's properties to cool houses down very easily. If water is slowly applied to the surface, we can cool the building and everything inside through evaporation - just like the Human Body does with sweating. (There's a wonderful paper from Hong Kong called "Photocatalytic construction and building materials: From fundamentals to applications" ... I can't link the .pdf, but it might be out there on the internet somewhere.)

So, I see a few things coming out of this. First, highways and roads can have median barriers replaced with something resembling a 'sponge', printed with a Dshape. TiO2 would either be part of the material, or applied later. I suspect that we could get higher surface areas that with precast, and thus passively clean air better.

Another one uses TiO2s properties to cool housing efficiently and thus saving money on AC. I'm really amazed by this possibility....mostly because it provides another reason for using 3D printing. Small holes for water would be part of the structure ... placed strategically to cool the whole building. The massive savings on energy costs would be a big part of selling large-scale 3D printing as a better bet in construction.

Anyways....i've been trying to figure out how to 3D model an ordinary Concrete median with Voronoi diagrams to get my idea across.....Meshlab keeps on crashing..woot! Autocad 2011 for Mac is still giving me trouble.....Having a mac is not the best for 3D design sometimes...

Lo vemos.

JF

Friday, June 3, 2011

Me and Maircos

After an hour on a hellish road in mountains of rock, bushes and the house/farm, you immediately notice the solar panels. To be specific, a steel tower with 6 170W panels lined up in a row, topped with a small wind turbine. Over the red clay roofs of Qoturi’s school, and framed by high mountains, it seems out of place. However, many outlying buildings had simple solar panels, indicating that clean energy was not a new technology to these parts. The wind turbine was a new aspect. Right next to the tower was a small white shack, which housed the batteries, the fuses and the controllers. What appeared to be an air vent chimney was in fact the post for the satellite connection that is promised to come within months.

A simple green fence is all that keeps people out, although, with a simple leap from the road above I could get inside. The entire design within the shack was neat and organized. A mysterious bird (or animal?) had made its nest within the tower, in the shade of the 6 170W panels. After some short deliberations, we decided to leave it be.

Adjacent to the installation was a 4 room 1 floor building with a kitchen, storage space, a room with a fridge and water filter system and a large room with 5 computers, a printer and a router. The computer room looked unused and cluttered. Thieves through a window had stolen 4 of the original computers weeks earlier, yet they left the power supplies, keyboard and mice. Steel bars and better locks had been added as a new precaution.

Laptops were placed on simple office tables with no chairs in sight. After logging onto the one computer that had not been stolen (and thus, most likely to be used) I found no evidence that kids had been using them. My failing was to not talk to the teachers about how the lab was being used. I expect that they are waiting for internet, but I have no clue at the moment. According to Marcelo, this installation got computers only 3 months ago. A projector was also stolen, yet replaced. Ricardo demonstrated it to local people (no children) with someone else translating to Quechua. I was not completely present because I was cleaning the solar panels.

I had a very revealing experience with a 4 year old named Maircos (sic?) who spoke some Castellanos but preferred Quechua. As I tapped away on one of the computers in the lab, he hung out with me and watched. I asked him whether or not he used a computer befor…. From his mute response, either he misunderstood me or maybe he thought he shouldn’t answer because no one had been allowed to use it. Clearly nobody had used the one leftover computer – there were no saved files of any sort or recently opened files in Word, Paint or MediaPlayer. Yet I could see his clear interest in me the Gringo and the weird looking TV. So I stopped and pulled out my Ipod Touch. As soon as I unlocked it with the slider, he smiled widely with bright eyes directed at me. I showed him how to go through photos and watch a video. I took a pictures of us two with the front-facing camera.

Later on I had to help out in the battery/control shack. A small appreciable crowd of local farmers, wives and schoolchildren stood on the other side of the fence while we ran through checks of the system. Maircos followed me inside the fence and clearly wanted to play more. For the benefit of him and the entire village it seemed, I showed him more. I opened the piano app and played Twinkle Twinkle Little Star. As soon as the first note was pressed, there was a small, yet audible murmur of surprise. After Maircos screwed around with the piano, I showed him Twinkle Twinkle and he got a bit of it. He was clearly enjoying himself, and to my slight relief, everyone present let me and Maircos have fun. I didn’t want to anyone to destroy the great times we were having, him and I. As we noodled away, the little kids stood very pilotely and watched, the women talked a little among themselves and the men looked on. The best part was the Sketchup App. At first, I drew a smiley face to demonstrate. Then I made a new page and let him draw. He drew a misshapened head with big eyes. Soon it turned into a game.

¿Esto hombre, él tiene una boca? (I point to my mouth)

(Maircos draws a mouth)

¿Esto hombre, él tendría un nariz? (I point to my nose)

(Maircos draws a nose)

¿Esto hombre, claro que sí él tendría pelo? (I lift a few strands of my hair)

(Maircos messily scratches out some hair)

After the whole ‘portrait’ was done, I showed the whole crowd what was drawn, which made them laugh loudly. Maircos was smiling, and so was everyone else. By then, other things had to be done, and we moved on. To his obvious sadness, he could not keep it. And my sadness as well.

To my obvious delight, it goes to show teaching kids computer literacy is a matter of prodding rather than lecturing. You have to show them a few things at first, but after that, you have to be a mentor rather than a teacher. Bless Señor Jobs for creating an intuitive user-interface. (and all those app-developers). I think if I had more time with Maircos, I would show him more of the Sketchup tools but in a round-about way. Instead of opening a certain tool, I’d say, “Nos debemos tocar esa botón. Vamos a ver que pasa!”

Indeed, what would happen?

A simple green fence is all that keeps people out, although, with a simple leap from the road above I could get inside. The entire design within the shack was neat and organized. A mysterious bird (or animal?) had made its nest within the tower, in the shade of the 6 170W panels. After some short deliberations, we decided to leave it be.

Adjacent to the installation was a 4 room 1 floor building with a kitchen, storage space, a room with a fridge and water filter system and a large room with 5 computers, a printer and a router. The computer room looked unused and cluttered. Thieves through a window had stolen 4 of the original computers weeks earlier, yet they left the power supplies, keyboard and mice. Steel bars and better locks had been added as a new precaution.

Laptops were placed on simple office tables with no chairs in sight. After logging onto the one computer that had not been stolen (and thus, most likely to be used) I found no evidence that kids had been using them. My failing was to not talk to the teachers about how the lab was being used. I expect that they are waiting for internet, but I have no clue at the moment. According to Marcelo, this installation got computers only 3 months ago. A projector was also stolen, yet replaced. Ricardo demonstrated it to local people (no children) with someone else translating to Quechua. I was not completely present because I was cleaning the solar panels.

I had a very revealing experience with a 4 year old named Maircos (sic?) who spoke some Castellanos but preferred Quechua. As I tapped away on one of the computers in the lab, he hung out with me and watched. I asked him whether or not he used a computer befor…. From his mute response, either he misunderstood me or maybe he thought he shouldn’t answer because no one had been allowed to use it. Clearly nobody had used the one leftover computer – there were no saved files of any sort or recently opened files in Word, Paint or MediaPlayer. Yet I could see his clear interest in me the Gringo and the weird looking TV. So I stopped and pulled out my Ipod Touch. As soon as I unlocked it with the slider, he smiled widely with bright eyes directed at me. I showed him how to go through photos and watch a video. I took a pictures of us two with the front-facing camera.

Later on I had to help out in the battery/control shack. A small appreciable crowd of local farmers, wives and schoolchildren stood on the other side of the fence while we ran through checks of the system. Maircos followed me inside the fence and clearly wanted to play more. For the benefit of him and the entire village it seemed, I showed him more. I opened the piano app and played Twinkle Twinkle Little Star. As soon as the first note was pressed, there was a small, yet audible murmur of surprise. After Maircos screwed around with the piano, I showed him Twinkle Twinkle and he got a bit of it. He was clearly enjoying himself, and to my slight relief, everyone present let me and Maircos have fun. I didn’t want to anyone to destroy the great times we were having, him and I. As we noodled away, the little kids stood very pilotely and watched, the women talked a little among themselves and the men looked on. The best part was the Sketchup App. At first, I drew a smiley face to demonstrate. Then I made a new page and let him draw. He drew a misshapened head with big eyes. Soon it turned into a game.

¿Esto hombre, él tiene una boca? (I point to my mouth)

(Maircos draws a mouth)

¿Esto hombre, él tendría un nariz? (I point to my nose)

(Maircos draws a nose)

¿Esto hombre, claro que sí él tendría pelo? (I lift a few strands of my hair)

(Maircos messily scratches out some hair)

After the whole ‘portrait’ was done, I showed the whole crowd what was drawn, which made them laugh loudly. Maircos was smiling, and so was everyone else. By then, other things had to be done, and we moved on. To his obvious sadness, he could not keep it. And my sadness as well.

To my obvious delight, it goes to show teaching kids computer literacy is a matter of prodding rather than lecturing. You have to show them a few things at first, but after that, you have to be a mentor rather than a teacher. Bless Señor Jobs for creating an intuitive user-interface. (and all those app-developers). I think if I had more time with Maircos, I would show him more of the Sketchup tools but in a round-about way. Instead of opening a certain tool, I’d say, “Nos debemos tocar esa botón. Vamos a ver que pasa!”

Indeed, what would happen?

Tuesday, May 31, 2011

Use of Computer and Internet Access to help children teach themselves in India.

Here's some great work by Sugata Mitra from the past ten years. I worked with a certain Dr. J. Harriss at SFU on a large paper analyzing Mitra's "Minimally Invasive Education". His argument that Education technology should be introduced to the poorest and remote areas of the world is very true. Children can't teach themselves more difficult subjects, but where education is extremely low-quality, or non-existent, they can pick up quite a lot of the basic math, science and literacy skills.

In the context of 3D printing in the third world, this sort of work meshes quite nicely. If 3D printing released the barriers to manufacturing the developing world, then MIE would release the creativity of its teeming masses. For poorer people who have the ability to craft 3D models that may serve a business they are in (and often self-employed) or a problem they may have (a broken part), then the shackles of the West's monopoly on technical solutions is broken.

Of course, designing complex parts is not easy. But often its a simple fix to a complicated machine they may have invested in. With the advent of reliable scanning it becomes easy to scan a broken part and then print it off. All it requires is some essential familiarity with computers, forums to answer questions and some patience.

Anyways, read my piece goddamn it. There are pictures of cute slum-urchins on computers. They're making LOL-Cats.

In the context of 3D printing in the third world, this sort of work meshes quite nicely. If 3D printing released the barriers to manufacturing the developing world, then MIE would release the creativity of its teeming masses. For poorer people who have the ability to craft 3D models that may serve a business they are in (and often self-employed) or a problem they may have (a broken part), then the shackles of the West's monopoly on technical solutions is broken.

Of course, designing complex parts is not easy. But often its a simple fix to a complicated machine they may have invested in. With the advent of reliable scanning it becomes easy to scan a broken part and then print it off. All it requires is some essential familiarity with computers, forums to answer questions and some patience.

Anyways, read my piece goddamn it. There are pictures of cute slum-urchins on computers. They're making LOL-Cats.

Monday, May 23, 2011

Bringing 3D Printing to Bolivia

I'm currently in Cochabamba, Bolivia as a volunteer for the Solar energy company Energetica, writing reports on the social-economic impact of their work on communities. On the side, I am also designing a 2-axis "Solar Tracker" for some of their smaller >150W systems. But not just any simple Solar Tracker. This is going to be a 3D printed, Arduino-powered Solar Tracker. And hopefully my prototype will be the first of many prototypes designed, printed and sold in Bolivia, and the Grand-daddy of a cheap reliable Solar Tracker.

Here are a few screenshots of the Motor case and Pivot which I designed with Google Sketchup (fig.1) and then simulated the print with Pleasant 3D to double-check the print quality (fig.2)

My lifelong interests of the problems of poverty and development as well as engineering and design collide quite neatly in the field of 3D printing. In places where it is difficult to create complicated parts quickly and cheaply, 3D printing fills the void. In a country where demand for relatively expensive durable items is fickle, on-demand printing is more economically viable. In a country where resources are scarce and a simple part means something very important to be working, this is economically valuable.

To prove this point, designing and manufacturing a cheap reliable solar tracker seemed like a challenge that a Makerbot or other 3D printer could handle. Ideally, it would have to be less than 100 dollars, last more than 15 years, be weather-resistant and consume less power than it would conceivably 'create'. In addition, it would have to be easy to print, easy to build and easy to install.

There are multiple ways of orienting panels towards the sun: a sensor tracks the position of the sun, a table of sun positions for every day of the year, or a formula that uses the current time and location. Sensors are prone to fail and cannot deal with oddities like...a cloud going past. It can become confused. A table of sun positions is a big table...bigger than the memory bank of the average Arduino microcontroller. However, using a clock, loading the geographical location and programming a formula could be much more reliable in all circumstances. The only drawback is that the system has to be active at all times. However, simplicity and reliability are first and foremost in such a design.

Lucky for me (a useless coder at best), there are a few codes out there that can calculate the position of the sun. Mowcius has developed an excellent open-source code that does everything we will need.

However, there are a few electronic and engineering issues that are beyond calculation and need to be resolved.

Can a stepper motor hold a 16 Kg, 150W panel?

-After searching high and low for good (yet inexpensive) stepper motors that had a holding torque of more than 200mN*cm, I realized that simply balancing the panel with a counterweight would do the trick. But this is a theory, and not practice. (I'll scan a drawing of my design soon)

How weather resistant is ABS plastic?

-Apparently, not very. After thinking about coating the plastic with a UV resistant paint, I realized that the entire system will probably be shaded by the panel! It remains to be seen what other problems would crop up after 15 years of sand, wind, indirect sunlight, dry-air, high altitude...etc. But the big problem can be mitigated.

Will the marginal increases in power generation cover the inevitable consumption by the tracker?

-According to our Wikipedia, 2-axis Solar Tracking Systems have an estimated 36% increase over fixed systems .... capturing almost 100% of direct and indirect light. (Grabs a napkin and pen) So, for a 150W system going from 74% to 100% is a mean increase of 54W. It is much more difficult to calculate energy output because of seasonal and daily changes in solar outputs. An Arduino Uno (5V) with a motor shield(5V), an RTC and 2 12V, 0.35amp Motors would consume ... 22V times ( 0.35(2) + 0.4 amps) = 24W ...

Decreasing these figures so we're not eating half the output increases (and probably the entirety of it in the morning and evening) is the next challenge. Preliminary research says its possible to sleep the Arduino or even turn it off (esp. since i have an RTC running in the background). The big question is the power consumption of the motors to hold the panel in position. In a perfect design, the motor would simply MOVE the panel and the structure would lock it until it needed to move it again. This is not important at the moment.

What about a once-in-a-decade Windstorm?

Again, that is a question for future prototypes. Keeping it simple and reliable is going to be a challenge!

Now that I've finished designing the 3D models, I need them printed. There are no Makerbotter's in Bolivia, so I'm hoping to crowdsource the printing until I can convince Energetica to buy a printer. If not this project is going to be stalled indefinitely.

JF

Here are a few screenshots of the Motor case and Pivot which I designed with Google Sketchup (fig.1) and then simulated the print with Pleasant 3D to double-check the print quality (fig.2)

My lifelong interests of the problems of poverty and development as well as engineering and design collide quite neatly in the field of 3D printing. In places where it is difficult to create complicated parts quickly and cheaply, 3D printing fills the void. In a country where demand for relatively expensive durable items is fickle, on-demand printing is more economically viable. In a country where resources are scarce and a simple part means something very important to be working, this is economically valuable.

To prove this point, designing and manufacturing a cheap reliable solar tracker seemed like a challenge that a Makerbot or other 3D printer could handle. Ideally, it would have to be less than 100 dollars, last more than 15 years, be weather-resistant and consume less power than it would conceivably 'create'. In addition, it would have to be easy to print, easy to build and easy to install.

There are multiple ways of orienting panels towards the sun: a sensor tracks the position of the sun, a table of sun positions for every day of the year, or a formula that uses the current time and location. Sensors are prone to fail and cannot deal with oddities like...a cloud going past. It can become confused. A table of sun positions is a big table...bigger than the memory bank of the average Arduino microcontroller. However, using a clock, loading the geographical location and programming a formula could be much more reliable in all circumstances. The only drawback is that the system has to be active at all times. However, simplicity and reliability are first and foremost in such a design.

Lucky for me (a useless coder at best), there are a few codes out there that can calculate the position of the sun. Mowcius has developed an excellent open-source code that does everything we will need.

However, there are a few electronic and engineering issues that are beyond calculation and need to be resolved.

Can a stepper motor hold a 16 Kg, 150W panel?

-After searching high and low for good (yet inexpensive) stepper motors that had a holding torque of more than 200mN*cm, I realized that simply balancing the panel with a counterweight would do the trick. But this is a theory, and not practice. (I'll scan a drawing of my design soon)

How weather resistant is ABS plastic?

-Apparently, not very. After thinking about coating the plastic with a UV resistant paint, I realized that the entire system will probably be shaded by the panel! It remains to be seen what other problems would crop up after 15 years of sand, wind, indirect sunlight, dry-air, high altitude...etc. But the big problem can be mitigated.

Will the marginal increases in power generation cover the inevitable consumption by the tracker?

-According to our Wikipedia, 2-axis Solar Tracking Systems have an estimated 36% increase over fixed systems .... capturing almost 100% of direct and indirect light. (Grabs a napkin and pen) So, for a 150W system going from 74% to 100% is a mean increase of 54W. It is much more difficult to calculate energy output because of seasonal and daily changes in solar outputs. An Arduino Uno (5V) with a motor shield(5V), an RTC and 2 12V, 0.35amp Motors would consume ... 22V times ( 0.35(2) + 0.4 amps) = 24W ...

Decreasing these figures so we're not eating half the output increases (and probably the entirety of it in the morning and evening) is the next challenge. Preliminary research says its possible to sleep the Arduino or even turn it off (esp. since i have an RTC running in the background). The big question is the power consumption of the motors to hold the panel in position. In a perfect design, the motor would simply MOVE the panel and the structure would lock it until it needed to move it again. This is not important at the moment.

What about a once-in-a-decade Windstorm?

Again, that is a question for future prototypes. Keeping it simple and reliable is going to be a challenge!

Now that I've finished designing the 3D models, I need them printed. There are no Makerbotter's in Bolivia, so I'm hoping to crowdsource the printing until I can convince Energetica to buy a printer. If not this project is going to be stalled indefinitely.

JF

Wednesday, April 13, 2011

Un-uniform Form

MIT investigates 3D printing at the large scale.

Money Quote -

".. input data about physical stresses on a structure, as well as design constraints such as size, overall shape, and the need to let in light into certain areas of a building. Based on this information, the software applies algorithms to specify how the material properties need to change throughout a structure.

Money Quote -

".. input data about physical stresses on a structure, as well as design constraints such as size, overall shape, and the need to let in light into certain areas of a building. Based on this information, the software applies algorithms to specify how the material properties need to change throughout a structure.

A load-bearing wall could be printed in elaborate patterns that correspond to the stresses it will experience from the load it supports from wind or earthquakes, for instance.

In non-load bearing areas, it could also be possible to print concrete that's so porous that light can penetrate, or to mix the concrete gradually with transparent materials."

Top marks to Neri Oxman for using ideas that Nature has developed and replicating it to produce more sustainable and structurally efficient buildings. I've been thinking along the same lines as she has - a polymer extruding head attached to a Dshape or other could go a long way to increasing the tensile strength...honeycomb patterns, voronoi structures or the like could be incorporated easily.

Re: The Original MIT article - they cite Behrokh Khoshnevis' printer, the Contour Printer....and not the Dshape.... Never a fan of his design compared to the Dshape - the potential to create freeform architecture is limited by its 'additive' design....Khoshnevis's feet are firmly encased in concrete and construction....nothing artistic can be created. I think next blog post Ill do a nice 'pros n cons' of the two.

Thursday, April 7, 2011

Free time with the Thing-o-matic

Spent about 6 hours with the Makerbot Thing-o-matic today....its a shared item at the Vancouver Hackerspace i frequent.

Fixed the heated platform - its important that the object being printed is kept at a certain temperature to prevent warping.

Printed the final part for a 3d scanner. Scanning will be happening soon I hope!

Printed a hand-hook

Printed parts for a elliptic gear system.

Printed my very own creation - a simple wheel.

And I dressed up the Makerbot ... I call him, Baron von Makerbot :)

Fixed the heated platform - its important that the object being printed is kept at a certain temperature to prevent warping.

Printed the final part for a 3d scanner. Scanning will be happening soon I hope!

Printed a hand-hook

Printed parts for a elliptic gear system.

Printed my very own creation - a simple wheel.

And I dressed up the Makerbot ... I call him, Baron von Makerbot :)

Monday, April 4, 2011

Dshape printed design wins Gold

Alright, a gardening medal from the Royal Horticultural Society in the UK. But damn, it looks nice! Same design was used in a public works project in Milan in April 2010. Goes to show of what the limitless possibilities here.

Sunday, April 3, 2011

3D printing and the 3rd World

As costs go down and the variety of printable materials go up, the number of users of 3D printing will increase. What does this mean for the Global South? Large stocks of semi-literate people, high inequalities, poor infrastructure characterize swaths of countries in Africa, Asia and South America. If the railroad brought together India, and the power-loom made China king of textile exports, what of 3D printing?

3D printing is not heavily dependent on major investors – its cost is decreasing rapidly. It does depend on computer literate operators and a steady source of electricity. It seems likely that the means of production will become increasingly decentralized. Small informal groups of 3D printers within urban centers will be much more common.

But what will they be making? In countries with fewer opportunities to make major reinvestment, retrofitting durable and capital goods rather than replacing them will become easier. In the case of a taxicab, replacing specialized parts will be a matter of 3D scanning (this technology has become increasingly cheap….I made one with a camera, a simple laser and a computer - $60), formatting on a computer and printing it. With good internet access, it might be possible to print off all the parts of a car.

This is just the inner futurist speaking – and nothing ages faster than predictions of the future. But the declining costs are a reality. 10 years ago, a quality 3D printer cost more than $50,000 dollars. Today, a desktop Makerbot costs $1,300 to make the equivalent quality. This has facilitated a boom in Do-It-Yourself printing in the Western world. Already in Germany DIY 3D metal printers have been made. The RepRap project was started in 2005 to create a printer that can print off its own parts to replicate itself.

During preceding decades the 1960s, 70s and 80s, many developing countries pursued Import Substitution Industrialization by raising tariffs on western products to protect their own small government-funded industries and markets. During the past 30 years, these tariffs were dropped and developing countries were forced to cut back on state-led industrialization. With the advent of 3D printing, it seems highly likely that industrialization will become highly decentralized and highly informal. 3D printing is likely to take-off within the Megacities of the Global South. Profitability will be depend on high demand for parts for consumer, durable and capital goods, quality infrastructure like electricity and the internet and a large work force of computer-literate designers and operators. No longer will state be able to direct industrial policy – its role may be that of a facilitator, and not a director of economic policy. For large conglomerates like the Tatas and the Mistubishis, their role is that of research and development rather than mass production. It is still far more cheaper and reliable to mass produce products.

Saturday, April 2, 2011

Voronoi Cell Structure

3D printing can produce structures which are inherently impossible to produce with current technologies (hand sculpting, molding and casting). That's its main advantage. The question is, how do we take advantage of these properties to its full extent?

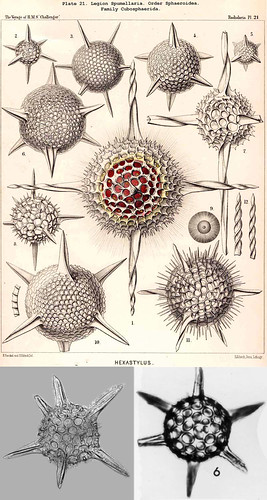

Enter Voronoi cells. These are statistical diagrams that are used in meteorology and physics, but also produce 2D and 3D structures that closely mimic nature. Compare multi-cellular seacreatures like Radiolaria and Voronoi cell diagrams below.

It gets better. Some recent Grad work by Eva Friedrich has used voronoi cells to find optimal structure formats to resist deformation of force on a simpler structure. To quoteth:

"It appears that a strength of the Voronoi diagram lies in the potential to produce interesting and unexpected structures which exhibit statically efficient system behaviour. Certain topologies which have emerged during the optimisation process apparently allow for ‘synergy’ effects of coordinated interactions of tear and pressure forces."

The take-away is pretty simple. It is possible to retune conventional structures and make them more organic and well as stronger. Along with 3D printing, it is possible to realize them in unheard manners.

There is a catch of course - the results can be ugly.

"....optimised structures generated with this technique, although performing better than the original structure, look irregular and random, with considerable distortion of the geometry of the structure."

If you look at the top left corner there's a picture of the first printed building by the Dshape - the Radiolaria. Now we have a mathematical way of recreating straight lines and mimicking nature without stealing all the blueprints - true inspiration!

Enter Voronoi cells. These are statistical diagrams that are used in meteorology and physics, but also produce 2D and 3D structures that closely mimic nature. Compare multi-cellular seacreatures like Radiolaria and Voronoi cell diagrams below.

It gets better. Some recent Grad work by Eva Friedrich has used voronoi cells to find optimal structure formats to resist deformation of force on a simpler structure. To quoteth:

"It appears that a strength of the Voronoi diagram lies in the potential to produce interesting and unexpected structures which exhibit statically efficient system behaviour. Certain topologies which have emerged during the optimisation process apparently allow for ‘synergy’ effects of coordinated interactions of tear and pressure forces."

The take-away is pretty simple. It is possible to retune conventional structures and make them more organic and well as stronger. Along with 3D printing, it is possible to realize them in unheard manners.

There is a catch of course - the results can be ugly.

"....optimised structures generated with this technique, although performing better than the original structure, look irregular and random, with considerable distortion of the geometry of the structure."

If you look at the top left corner there's a picture of the first printed building by the Dshape - the Radiolaria. Now we have a mathematical way of recreating straight lines and mimicking nature without stealing all the blueprints - true inspiration!

Friday, April 1, 2011

Bad prints and reusing ABS

In my times using the Makerbot, there have been quite a few 'bad prints'. The platform skips, the extruder runs out/can't pull enough ABS/PLA plastic, warping. But ABS is expensive, and it is reusable. The same goes for PLA. I wonder how easy it would be to develop a system that melts and reshapes the plastic into long strings. Better yet, a system that goes with the extruder so that a bad print can be tossed into a funnel and reprinted.

I can't see why this hasn't happened yet! Maybe its a matter of time.

I can't see why this hasn't happened yet! Maybe its a matter of time.

Thursday, March 31, 2011

Will 3D Printing Kill Jobs?

A question on the forefront of many within the manufacturing and design industry, and with the advent of large scale 3D printing, a big question for the construction industry. Fabbaloo raised the same question in their blog, quoting several economic and business texts.

Essentially, barriers to entry become lower (start-up costs and time to pay of debt). In that case, competition for customers becomes fiercer, forcing many established companies to shed variable capital costs (eg. Labour). The flipside is that products may become cheaper - 3D printing is at a stage where only the most basic techniques are widely available. Makerbot, RepRap use ABS and PLA plastics and additive techniques..CNCs and draftbots use drills, wood and ink....but overall, there are major limitation in what they can make. So perhaps jobs will be lost in just particular sectors.

Intellectual property of physical products are threatened - what has not been disclosed in the news about 3D printing is that 3D scanning is getting better and cheaper too. I am currently working on my own design for one....costs so far: 45 bucks. Simplistic designs can be copied and reproduced - toys and games. Open Sourcing of designs along with community effort to improve said designs have made Thingiverse and Shapeways the touchstones they ought to be. The problem is that existing designs and all the hardwork involved in their R+D are threatened. Why make a product when you can copy someone else? Why make a product if I can't make money of it? Well, there is no replacement for good quality....and that still matters...let me illustrate this.

Imagine a world where there are thousands of 'print shops' that can make virtually any part with any material. A part blows up in your car, the master cyclinder. You reconstruct it, you scan it, send it to the shop, and they use laser sinistration to make the part. Money and time is saved. Quality it may not - that is the catch with 3D printing and scanning for the next decades...low quality. And the only thing holding the bottom of any industry is doing their job right..producing quality products.

Lets talk about the Dshape's impact on the US construction industry which is made up of 710,307 companies and contractors, makes 1.2 Trillion and pays out 250 Billion to 7 million employees. The Dshape can make a lot of basic masonry as well as building structures. It also needs 2 people to run it and is completely automated. For concrete makers and users, this is a serious threat. Yet for carpenters, landscapers and every other industry involved with finishing, there is a big advantage. They will have plenty of business to finish the shells of these buildings. Not only that, carpenters can use cheap CNC machines to produce customized products. Landscapers can make customized garden ornaments with the Dshape. Most importantly, it reduces costs of house building. Arguably, it opens up the possibilities of design. As Thingiverse and Shapeways have demonstrated, Open Source and 3D printing are meant to go together. Large Scale 3D printing of buildings will have to step up and change the Construction Industry and bring it into the Open Source fold.

Open Source changes the mode of work, and i believe it makes for more productive workers. I certainly believe that industry will become even more diffuse and atomized, which can often strengthen an industry rather than weaken it. For the construction industry, that could be a major boon.

Essentially, barriers to entry become lower (start-up costs and time to pay of debt). In that case, competition for customers becomes fiercer, forcing many established companies to shed variable capital costs (eg. Labour). The flipside is that products may become cheaper - 3D printing is at a stage where only the most basic techniques are widely available. Makerbot, RepRap use ABS and PLA plastics and additive techniques..CNCs and draftbots use drills, wood and ink....but overall, there are major limitation in what they can make. So perhaps jobs will be lost in just particular sectors.

Intellectual property of physical products are threatened - what has not been disclosed in the news about 3D printing is that 3D scanning is getting better and cheaper too. I am currently working on my own design for one....costs so far: 45 bucks. Simplistic designs can be copied and reproduced - toys and games. Open Sourcing of designs along with community effort to improve said designs have made Thingiverse and Shapeways the touchstones they ought to be. The problem is that existing designs and all the hardwork involved in their R+D are threatened. Why make a product when you can copy someone else? Why make a product if I can't make money of it? Well, there is no replacement for good quality....and that still matters...let me illustrate this.

Imagine a world where there are thousands of 'print shops' that can make virtually any part with any material. A part blows up in your car, the master cyclinder. You reconstruct it, you scan it, send it to the shop, and they use laser sinistration to make the part. Money and time is saved. Quality it may not - that is the catch with 3D printing and scanning for the next decades...low quality. And the only thing holding the bottom of any industry is doing their job right..producing quality products.

Lets talk about the Dshape's impact on the US construction industry which is made up of 710,307 companies and contractors, makes 1.2 Trillion and pays out 250 Billion to 7 million employees. The Dshape can make a lot of basic masonry as well as building structures. It also needs 2 people to run it and is completely automated. For concrete makers and users, this is a serious threat. Yet for carpenters, landscapers and every other industry involved with finishing, there is a big advantage. They will have plenty of business to finish the shells of these buildings. Not only that, carpenters can use cheap CNC machines to produce customized products. Landscapers can make customized garden ornaments with the Dshape. Most importantly, it reduces costs of house building. Arguably, it opens up the possibilities of design. As Thingiverse and Shapeways have demonstrated, Open Source and 3D printing are meant to go together. Large Scale 3D printing of buildings will have to step up and change the Construction Industry and bring it into the Open Source fold.

Open Source changes the mode of work, and i believe it makes for more productive workers. I certainly believe that industry will become even more diffuse and atomized, which can often strengthen an industry rather than weaken it. For the construction industry, that could be a major boon.

Manifesto of Done and other thoughts

Cruising through Make Magazine's blog and I noticed a post titled: "The Cult of Done Manifesto". Written by Bre Pettis (founder of Makerbot) and Kio Stark, it outlines 13 simple rules to follow. Best way to sum it up? Just do it.

The Cult of Done Manifesto

The Cult of Done Manifesto

- There are three states of being. Not knowing, action and completion.

- Accept that everything is a draft. It helps to get it done.

- There is no editing stage.

- Pretending you know what you're doing is almost the same as knowing what you are doing, so just accept that you know what you're doing even if you don't and do it.

- Banish procrastination. If you wait more than a week to get an idea done, abandon it.

- The point of being done is not to finish but to get other things done.

- Once you're done you can throw it away.

- Laugh at perfection. It's boring and keeps you from being done.

- People without dirty hands are wrong. Doing something makes you right.

- Failure counts as done. So do mistakes.

- Destruction is a variant of done.

- If you have an idea and publish it on the internet, that counts as a ghost of done.

- Done is the engine of more.

Wednesday, March 30, 2011

First Post!!1!

This is the first post of what I hope is going to be a lot of fun. Talking about my thoughts and progress with 3D printing.

There's a revolution ready to happen, and I intend to be right there when it happens.

But where and when?

Well as lots of people may be aware, 3D printers have become very cheap - The RepRap and Makerbots Thingomatic are prominent examples. But it is still firmly in the realm of hobbyists. More advanced high-quality (and reliable) printers are far too expensive at the moment, only available to companies, universities and Richie Rich.

Although nothing ages faster than predictions of the future, I predict that in 10 years we could be able to buy these printers for less than 500 bucks. We are forgetting the fact that these printers can make their own parts. If the ease and cost of making almost every part is low enough, anyone can enter the market and compete, driving the cost down.

But I'm not expressly interested in 3d printing at that scale. I'm thinking about 3D printing buildings. This has been done already.

The Dshape printer was developed by Enrico Dini, and patented last year. It can print objects as big as 6 x 6 meters (height is unknown...possibly 6+). In essence, nozzles spray a chemical ink over a layer of sand in discreet areas which harden in time for the process repeated. Its simple, effective and revolutionary.

In my conversations with Dini, the constructive quality and resolution is not high enough to create buildings from scratch - there are major limitations. However, these limitations are not as difficult to overcome.

In the meantime, there are limitless options for making money - artificial stones and objects, statues, sculptures, moldings, small sheds or shelters, molds for casting concrete or other objects. It comes in dolomite, grey or granite colours...not much variation at this point.

So the question for me can we take advantage of this technology and get a headstart on competitors? (There are - http://www.contourcrafting.org/) Obviously, market to virtually everyone. The start-up costs are somewhat prohibitive - a single 6 x 6 Dshape printer costs 280,000 Euros. However, the running costs are not as much you would expect. Electricity consumption is not high (peak 40 kWh, usually 2kWh), materials are not terribly expensive. At 15 - 30 cm of layering a day, a small bus shelter of 2.5 m would take 1-2 weeks! Plus, any screw ups would badly affect speedy production.

In retrospect, the technology has gone pretty far in the 5 years it has been moving, and following the speed of small scale 3D printing, we can expect reliability and quality in large scale printing to go up.

With the right investment, of course. That is my challenge.

There's a revolution ready to happen, and I intend to be right there when it happens.

But where and when?

Well as lots of people may be aware, 3D printers have become very cheap - The RepRap and Makerbots Thingomatic are prominent examples. But it is still firmly in the realm of hobbyists. More advanced high-quality (and reliable) printers are far too expensive at the moment, only available to companies, universities and Richie Rich.

Although nothing ages faster than predictions of the future, I predict that in 10 years we could be able to buy these printers for less than 500 bucks. We are forgetting the fact that these printers can make their own parts. If the ease and cost of making almost every part is low enough, anyone can enter the market and compete, driving the cost down.

But I'm not expressly interested in 3d printing at that scale. I'm thinking about 3D printing buildings. This has been done already.

The Dshape printer was developed by Enrico Dini, and patented last year. It can print objects as big as 6 x 6 meters (height is unknown...possibly 6+). In essence, nozzles spray a chemical ink over a layer of sand in discreet areas which harden in time for the process repeated. Its simple, effective and revolutionary.

In my conversations with Dini, the constructive quality and resolution is not high enough to create buildings from scratch - there are major limitations. However, these limitations are not as difficult to overcome.

In the meantime, there are limitless options for making money - artificial stones and objects, statues, sculptures, moldings, small sheds or shelters, molds for casting concrete or other objects. It comes in dolomite, grey or granite colours...not much variation at this point.

So the question for me can we take advantage of this technology and get a headstart on competitors? (There are - http://www.contourcrafting.org/) Obviously, market to virtually everyone. The start-up costs are somewhat prohibitive - a single 6 x 6 Dshape printer costs 280,000 Euros. However, the running costs are not as much you would expect. Electricity consumption is not high (peak 40 kWh, usually 2kWh), materials are not terribly expensive. At 15 - 30 cm of layering a day, a small bus shelter of 2.5 m would take 1-2 weeks! Plus, any screw ups would badly affect speedy production.

In retrospect, the technology has gone pretty far in the 5 years it has been moving, and following the speed of small scale 3D printing, we can expect reliability and quality in large scale printing to go up.

With the right investment, of course. That is my challenge.

Subscribe to:

Posts (Atom)